Understanding the Difference Between RTV and LSR Silicone in Manufacturing

Understanding the Difference Between RTV and LSR Silicone in Manufacturing Silicone is a versatile material used in a wide variety of industries, from automotive and

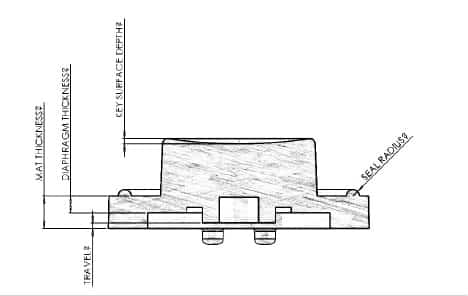

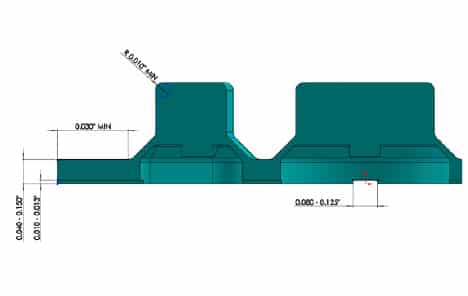

Silicone Rubber Molding Design: Rules and Recommendations

Welcome to our guide on the essential rules and recommendations for designing silicone rubber molded products. Our approach combines technical precision with practical guidelines to ensure the highest quality in your molded devices and components.

1. Manufacturability Musts:

2. Dimensional Standards:

3. Keypad Design Specifications:

4. Keypad Mat Thickness:

5. Backlighting Integration:

6. Shrinkage and Tolerance Considerations:

7. Comprehensive Design Checklist:

With over 75 years of experience in silicone keypad design and molding, we are committed to providing complete customer satisfaction with the highest quality products in a successful and timely manner. The customer is and has always been the focus of our business.

Understanding the Difference Between RTV and LSR Silicone in Manufacturing Silicone is a versatile material used in a wide variety of industries, from automotive and

Welcoming the New Year: Celebrating the Importance of U.S. Manufacturing As we usher in the New Year, it’s the perfect time to reflect on our

Best Practices for Cleaning Silicone Rubber: Keeping Your Components in Top Shape Silicone rubber is prized for its durability, flexibility, and resistance to extreme temperatures,

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.