Terminology

Terminology for Silicone Keypads and Components

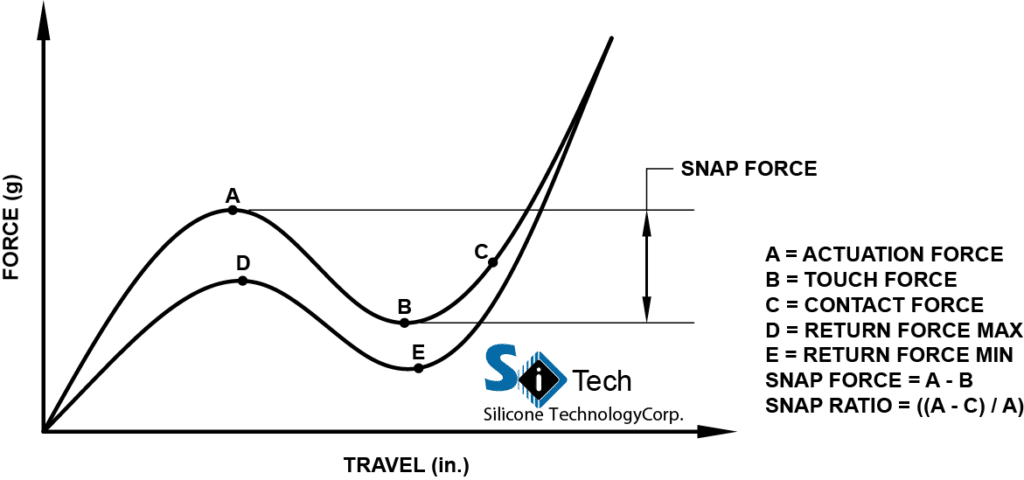

Actuation Force

The amount of force required to collapse the diaphragm (web) of a rubber keypad. This force can be used in combination with polydomes, metal domes, mechanical switches, or rubber-only keypads.

Air Channel

A series of air paths located on the underside of rubber keypads, designed to allow air to escape as the keypad is depressed.

Alignment Hole

A through-hole in the rubber keypad that aids in positioning the keypad within its enclosure for precise alignment.

Base Matte (Mat)

The silicone sheet material that connects all keys on a rubber keypad, forming a base layer. This is also referred to as the “mat.”

Bezel

The faceplate or cover, typically made of plastic or metal, that secures the keypad to the printed circuit board or switch assembly.

Bosses

Small raised posts on the keypad used for the positive alignment of the rubber keypad within the bezel or assembly.

Compression Set

The ability of silicone material to return to its original size and shape after being compressed under specific conditions. This is critical for maintaining the functionality and longevity of rubber keypads.

Conductive Rubber

Silicone rubber that has been impregnated or coated with conductive materials to create electrical pathways when depressed.

Color Matching

The process of visually and electronically analyzing mixed silicone rubber material to match it with a specified color sample. SiTech uses the Pantone Matching System (PMS) to achieve precise color matches within a 1 Delta-E variation.

Diaphragm (Web)

The thin, flexible section of a silicone key that enables movement when the key is pressed. The design of this area is critical to the tactile feel and functionality of the keypad.

Durometer

A measurement of the hardness of silicone rubber, typically expressed on the Shore A scale. The durometer value determines the flexibility and durability of the material.

Key Height

The distance from the bottom of the keypad (base mat) to the top surface of a key. This dimension is important for ensuring the correct tactile response and ergonomic functionality of the keypad.

Legend

Printed graphics, such as symbols, letters, or numbers, that appear on the surface of the silicone keys. Legends are typically created using screen printing or laser marking techniques.

Life

The number of actuations a rubber diaphragm or web can withstand before rupturing or losing functionality. This measure is crucial for determining the durability and longevity of a keypad.

Positive-Image Graphics

Graphics that are printed directly on top of the silicone key surface, often in one or more colors, to create visible legends or symbols.

Reversed-Out Graphics

A graphic design technique where the rubber’s natural color or a masked color shows through the top layer of printing, creating a visual contrast with the printed areas.

Snap Ratio

A measurement related to the tactile feedback of a key, calculated using the formula (A-C)/A, where A is the actuation force and C is the return force. This ratio helps define the “snap” feel of the key.

Stroke (Travel)

The distance from the resting position of the rubber key to the fully depressed position, indicating how far the key travels when pressed.

Swell

The increase in volume of silicone rubber when exposed to petrochemicals over time. This factor is important when designing keypads for environments where chemicals are present.

Tactile Feel

The feedback a user feels when pressing a key. In tactile silicone keypads, the design of the diaphragm (web) is essential to providing a responsive, satisfying tactile feel.

Tear Strength

A measure of silicone’s resistance to tearing when subjected to force. Tear strength is calculated by dividing the maximum force load by the thickness of the material.

Wear (Abrasion Resistance)

The ability of printed graphics or coatings to withstand wear over time. Wear resistance is tested using a Norman tester, which measures how many cycles the keypad can endure before visible wear occurs.

For additional information or questions, please contact us at 757-887-8488.