Red, White, and Built to Spec: How U.S. Manufacturers Support Defense & Aerospace Better

Red, White, and Built to Spec: How U.S. Manufacturers Support Defense & Aerospace Better When precision, reliability, and compliance matter most, offshore manufacturing just doesn’t

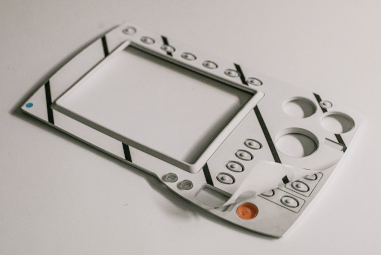

At SiTech, we offer proprietary silicone-based coating systems that are specifically engineered to enhance the performance and durability of silicone rubber keypads and components. Our coatings form a cross-link bond with the silicone rubber, ensuring that the coating becomes an integral part of the keypad itself. This bond prevents cracking, peeling, or degradation over time, maintaining the genuine silicone feel while providing exceptional protection against wear, chemicals, and environmental factors.

At SiTech, we offer proprietary silicone-based coating systems that are specifically engineered to enhance the performance and durability of silicone rubber keypads and components. Our coatings form a cross-link bond with the silicone rubber, ensuring that the coating becomes an integral part of the keypad itself. This bond prevents cracking, peeling, or degradation over time, maintaining the genuine silicone feel while providing exceptional protection against wear, chemicals, and environmental factors.