When it comes to molding complex and intricate parts, planning is the key to success. One of the best advantages liquid silicone rubber molding offers that traditional plastic molding does not is undercuts. Undercuts are recessed surfaces that will interfere with the de-molding process. With silicone rubber this is not the case. When planned correctly, undercuts can add design features to your final components that would not be available with other materials. These include mounting options for custom silicone keypads, or channels and grooves for mounting custom windows for displays.

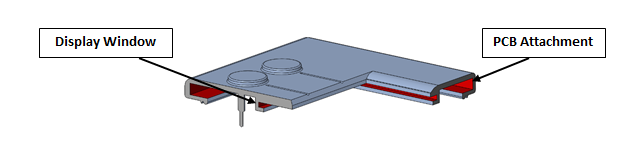

Undercuts can come in a variety of shapes and sizes, as well as complexities. Utilizing undercuts on your silicone rubber components and keypads can allow for a variety of features. These features are typically used for connecting the undercut component to another. Channels or grooves are some of the most frequently used features as they allow the placement of the part onto a printed circuit board (PCB). Components and keypads can utilize multiple undercuts as well, each being used for a different purpose. This works well in the case of needing to hold a display window as well as attach to a PCB.

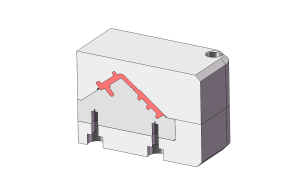

Typically simple undercuts have no effect on the removal of the part from the mold. When undercuts are complex, or are too deep, they may require the use of a tool or special mold to remove the part during the de-molding process. Sometimes, an extensive knowledge of liquid silicone injection molding is needed when planning and executing the design of a complex undercut mold. The design for de-molding a component is just as important as the design for molding a component. Silicone has a high tear strength as well as elasticity, which means that parts can typically be stretched over the undercut areas during the de-molding process, and the parts will still retain their desired shape and size.

Undercut designs in custom silicone rubber keypads can help your product stand out in appearance with a clean finished look. Expertise in the industry is needed when designing undercuts into your product, especially when tight tolerances need to be achieved. At SITECH we have the experience to help with design and production of the highest quality silicone rubber keypads available. If you are looking for more information on undercut components or keypads you can give us a call today. You can speak with one of our engineers, or sales department by calling: 757-887-8488 or using our contact form to request a quote today.

Undercut designs in custom silicone rubber keypads can help your product stand out in appearance with a clean finished look. Expertise in the industry is needed when designing undercuts into your product, especially when tight tolerances need to be achieved. At SITECH we have the experience to help with design and production of the highest quality silicone rubber keypads available. If you are looking for more information on undercut components or keypads you can give us a call today. You can speak with one of our engineers, or sales department by calling: 757-887-8488 or using our contact form to request a quote today.