Liquid silicone rubber molding offers great advantages over traditional plastic molding. And one of the greatest advantages is the use of undercuts. Utilizing undercuts correctly in your silicone rubber product design can significantly improve the overall quality of your final product. When used properly, undercuts can add design features to your rubber product that would never be available with other materials. Some of these include, mounting options for custom silicone keypads, and channels and grooves for displays.

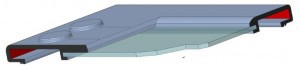

An undercut design when dealing with liquid injection molding can be defined as a depression that allows the flow of silicone or a protrusion that prohibits the flow. The depression or protrusion will then create a groove or channel that can aid in the placement of the silicone rubber part onto a printed circuit board, or gives the option to mount a variety of materials into the silicone rubber. This can be seen in Figure 1-1 below. Figure 1-1 shows two undercuts. The first undercut (highlighted Red) would be utilized by mounting the silicone rubber keypad onto a printed circuit board. The second undercut is being utilized by having a clear glass window mounted into it. This undercut would be used for protective coverings for display units.

Undercuts have varying geometry and complexity. Depending on the requirement, they can be square, rounded, deep and shallow. The options are vast when designing your silicone rubber components or keypads. Undercut designs can be useful in parts where pull through tabs or spigots are not an option. These “spigots” typically are pushed or pulled through an opening in the printed circuit board to align and secure the keypad to the board. A proper undercut design can eliminate the need for these altogether. While not only simplifying the overall design, a proper undercut can provide protection for vital components against moisture and other damaging conditions.

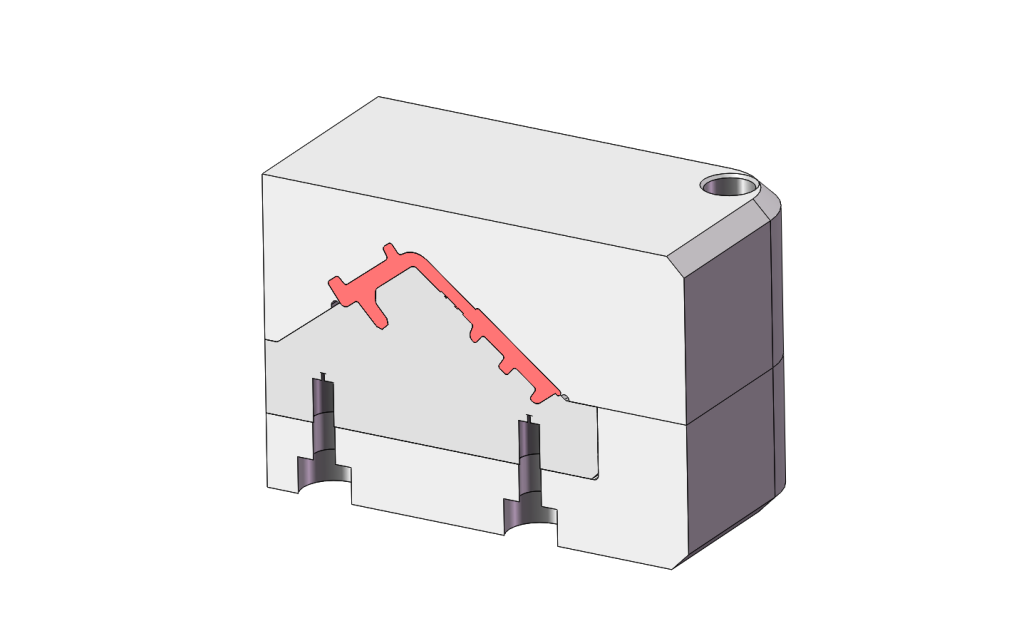

Typically simple undercuts have no effect on the removal of the part from the mold. When undercuts are complex, or are too deep, they may require the use of a tool or special mold to remove the part during the de-molding process. Sometimes, an extensive knowledge of liquid silicone injection molding is needed when planning and executing the design of a complex undercut mold. The design for de-molding a component is just as important as the design for molding a component. Silicone has a high tear strength as well as elasticity, which means that parts can typically be stretched over the undercut areas during the de-molding process, and the parts will still retain their desired shape and size. Figure 1-2 below shows an unorthodox mold design of a part that contains various undercuts.

Undercut designs in custom silicone rubber keypads can help your product stand out in appearance with a clean finished look. Expertise in the industry is needed when designing undercuts into your product, especially when tight tolerances need to be achieved. At SiTECH we have the experience to help with design and production of the highest quality silicone rubber keypads available. If you are looking for more information on undercut components or keypads you can give us a call today. You can speak with one of our engineers, or sales department by calling: 757-887-8488 or using our contact form to request a quote today.