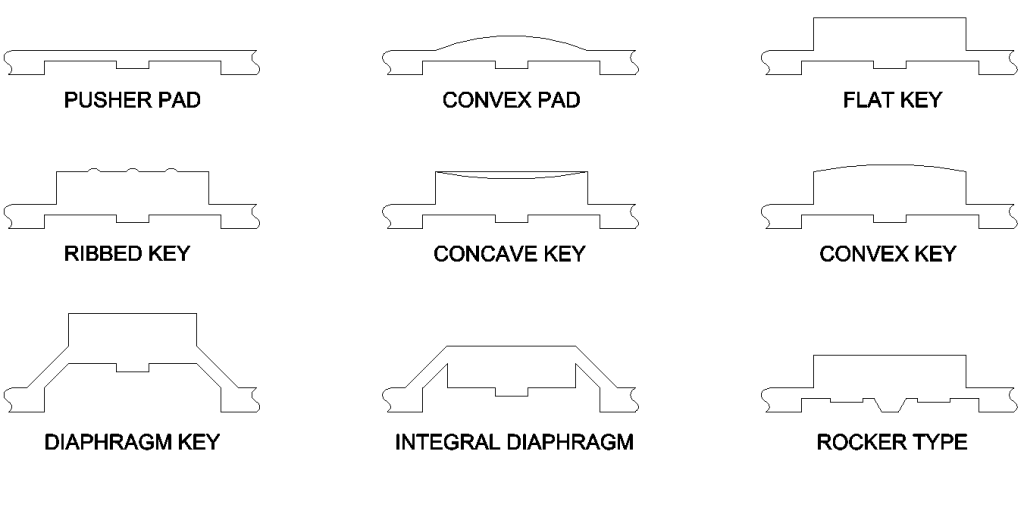

Silicone molded keypads made at SiTECH are used in countless devices from aviation equipment to medical devices. These devices all have different requirements which require specific key types to be used. Below is a diagram showing the different key types typically used on our customers silicone rubber keypads.

Most of these key types do not provide a tactile feel or “snap” of the rubber. The two Diaphragm type keys do provide a tactile feel which is further explained in the Diaphragms portion of this design guide. For the other types, it is recommended to use a metal dome for a tactile response.

Metal domes are the new standard for switch contacts. Previously, carbon pills were the standard for switch contacts, which while they are still being used, do not provide a tactile response with certain key types. This drastically decreased the number of key types that were able to be used on a tactile silicone rubber keypad. The utilization of metal domes has significantly increased the key types that are able to be used on silicone keypads. This is because the dome itself is the source of the tactile feedback and shorting switch.

Terminology:

Actuation Force: The force required to collapse the web of a rubber keypad in conjunction with polydome, metal dome, mechanical switch or rubber only.

Air Channel: Air path(s) on the bottom of rubber keypads that allows for air passage when rubber is depressed.

Alignment Hole: Through hole in rubber keypad that is used to position keypad in enclosure.

Base Matte: Silicone sheet material that joins all keys on a rubber keypad. Also known as mat.

Bezel: The faceplate or cover, typically plastic or metal, used to secure a keypad to a printed circuit board or switch.

Bosses: Small posts used for positive alignment of rubber keypad in bezels or assemblies.

Compression Set: The measurement of a material’s ability to recover its original size and shape after compression under prescribed conditions.

Conductive Rubber: Silicone keypad impregnated/coated with conductive material.

Color Matching: The visual and electronic analysis of a mixed silicone rubber material compared to a supplied color sample.

Diaphragm / Web: The thin hinged area that permits a rubber key to flex.

Durometer: A measurement range of hardness for silicone rubber.

Key Height: The measured distance from the bottom of a keypad (base matte) to the top surface of a key.

Legend: Printed graphic (symbol, letter or number) on the top of the rubber surface.

Life: The number of actuations realized before the rubber diaphragm/web ruptures.

Reversed-Out Graphics: Graphics that allow rubber color or masking color to be seen through top surface printing on keypad.

Positive-image Graphics: Single or multi-color printing on top of key surface.

Stroke / Travel: Distance from the contact surface of a rubber part to a surface.

Swell: The increase in volume of rubber when in contact with petrochemicals for a determined period.

Tactile Feel: The response of rubber while depressing. For tactile rubber keypads, it is a critical function of the diaphragm web geometry.

Tear Strength: The tear strength is a measure of the resistance of rubber to tear forces. The tear strength is calculated by dividing the maximum force load by the thickness of the rubber.

Wear or abrasion resistance: The resistance of a particular ink or coating to manual wearing. The testing process is usually a Norman tester with the number of cycles legends can perform before wear is noticeable.