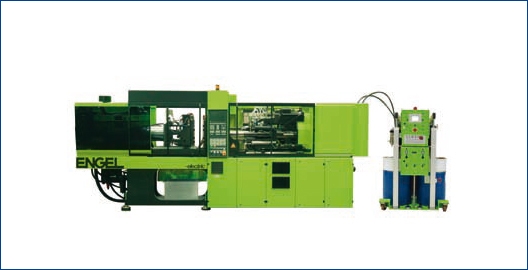

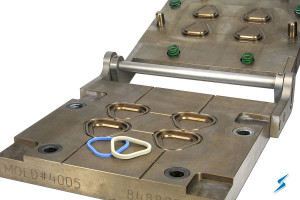

The process for injection molding liquid silicone rubber is a multistep process. Liquid silicone is provided in 2 barrels, an A and a B. The silicones viscosity allows them to be able to be pumped through hoses at using a metering pump. The pump also can shoot a specified amount of material pigment, that when mixed with the silicone gives the silicone its specified color. The material is then mixed together, which when done creates a homogeneous material, that is very consistent throughout the entire part. When material from barrel A is mixed with material from barrel B, the vulcanization process begins. The material then is drawn into the barrel and is ready for injection. The molds used in the injection molding of liquid silicone rubber are heated to temperatures ranging from approximately 250° – 300°. The silicone is injected into the hot mold via a sprue and runner system that when designed correctly should evenly distribute the liquid silicone rubber into the keypads or components. This whole process is a “Closed – loop” system which means that no contamination or handling of the liquid silicone occurs from the time the material is loaded into the machine until the material is injected into the mold.

The process for injection molding liquid silicone rubber is a multistep process. Liquid silicone is provided in 2 barrels, an A and a B. The silicones viscosity allows them to be able to be pumped through hoses at using a metering pump. The pump also can shoot a specified amount of material pigment, that when mixed with the silicone gives the silicone its specified color. The material is then mixed together, which when done creates a homogeneous material, that is very consistent throughout the entire part. When material from barrel A is mixed with material from barrel B, the vulcanization process begins. The material then is drawn into the barrel and is ready for injection. The molds used in the injection molding of liquid silicone rubber are heated to temperatures ranging from approximately 250° – 300°. The silicone is injected into the hot mold via a sprue and runner system that when designed correctly should evenly distribute the liquid silicone rubber into the keypads or components. This whole process is a “Closed – loop” system which means that no contamination or handling of the liquid silicone occurs from the time the material is loaded into the machine until the material is injected into the mold.

Injection molding has a few advantages over the competition, which mainly consists of compression molding. These advantages include:

- Reduced cycle time

- Keypads and components typically have a cycle time of approximately 30 seconds – 2 minutes. This drastically increases the amount of production output vs compression molding.

- Flash-less tooling

- Liquid silicone injection molds inject the silicone after the mold has closed, and with the use of flash rings, vent tracks, and a well-designed runner system the tooling leaves little to no flash on the parts. This decreases the amount of time needed to de-flash and trim the part.

- No Pre-forms needed

- Liquid silicone rubber injection molding requires no pre-forms. A pre-form is a basic shape of the end product that is placed into each cavity during compression molding. These pre-forms need to be a surplus of material which insures a total cavity fill of material. The excess material is pressed between the two molds causing flash around all of the cavities.

- Production of insert molded components

- Injection molding silicone rubber allows for the placement of pre-molded clear silicone inserts within the tool. The clear silicone inserts become “over-molded” with the desired color creating a seamless bond between the insert and over-mold. This allows for the blockage of light between keys and eliminates the need for the customer to design custom light blocking components within the PCB. The clear inserts can also be used for display windows to show components or digital screens behind the silicone keypad. The cross-link bond that over-molding silicone inserts creates, allows for a leak-proof keypad or component.

- There is minimal material waste when using injection molding

- Material is only wasted within the sprue and runner system leading to the component or keypad, and this can be eliminated with the use of a cold runner system. Cold runner systems keep the silicone cool within the runner and sprue to keep the silicone from curing. These systems are typically only used on large quantity orders where the material waste begins to have an effect on the cost.

If you have questions or concerns about how liquid silicone injection molding can make your product better, contact our office today at 757-887-8488 or by submitting a quote here. We’re located in Virginia and do all of our manufacturing on-site.