Molded liquid silicone rubber keypads and components shrink after the demolding process. The materials we use at SiTech typically shrink approximately 2-3% after the demolding process. There are a few factors that will cause the part shrinkage to be difficult to predict.

They Include:

- The mold temperature.

- The more heat applied to the silicone, the more the silicone will expand within the mold. Higher mold temperatures cause higher shrink percentages.

- The demolding temperature.

- Injection pressure within the cavity of the mold.

- The location of the injection point, or gate into the part.

- Part shrinkage in the flow from the injection point is usually much higher than perpendicular to the injection point.

- The dimensions of the part.

- Thicker cross sections shrink less than smaller cross sections.

If a post cure is required for your component, it will add an additional 0.5-1% of shrinkage. There are a few reasons why your part may need to be post cured. The first is if used in a Food Grade application. Post curing removes the volatile components and low weight cyclics from the silicone. Another reason why post-curing may be used is to enhance the compression set of the silicone rubber. The supplier of the silicone rubber used here at SiTech recommends a 4 Hour post cure at 400° F.

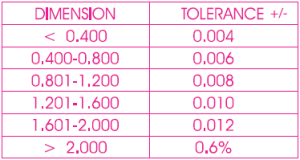

Due to the variable shrinkage, a part can have, liquid silicone rubber components are limited to the tolerances that can be applied. Here at SiTECH, we have determined the tightest tolerances we are capable of. As shown below in our tolerance chart, our tolerances vary from your standard Class M2 and are more closely represented by the Class M1 tolerances in ISO 3302.

SiTECHech is able to control shrinkage better than the industry standards. If you are in need of a quotation or would like to know more you can call us at: 757-887-8488, or submit and RFQ here.