How Modular Controls Can Offer Your Customers More Options

Options are great for your customers because it puts them in the driver’s seat to customize a package that suits their needs exactly. As you

Options are great for your customers because it puts them in the driver’s seat to customize a package that suits their needs exactly. As you

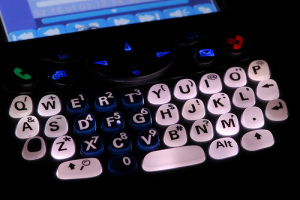

Silicone keypads still reign supreme over other alternatives ranging from plastic to touchscreen. While those other alternatives may have a place in some applications and

From audio-visual equipment to telephones and point of sale systems, there are many keypads that require the ability of backlighting to ensure better visibility by

From experience and ITAR compliance to USA made products and stellar customer service, there are many reasons to trust SiTech as your silicone rubber keypad

If you are in the medical field, whether you own a hospital or manage an urgent care center, you understandably want the best equipment possible

Advances in the military are staggering in terms of technology and state of the art weaponry. But a lesser known aspect of the military’s needs

In short, we like compliance. We like knowing we’re at the top of our game when it comes to supporting our contractors with durable silicone

There are distinct differences between the two, ranging from ease of use to functionality to look and feel. Certain work applications may work best with

Rubber molding for keypad design has many benefits, not the least of which is due to its versatile nature. It’s what holds the entire piece

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.