Graphic Design Considerations

Design is an integral component of any keypad. We talk a lot about the functionality of keypads and how silicone is the best and most

Design is an integral component of any keypad. We talk a lot about the functionality of keypads and how silicone is the best and most

SiTECH has been at the forefront of laser marking for years now, and we know the value it brings to a variety of industries. So,

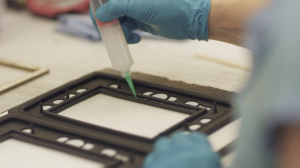

Ever wonder how the silicone keypad featured on your medical devices and manufacturing machinery has been assembled? It’s a complex, fascinating process that has many

What’s it all about? Did you know rapid prototyping can take your design from paper to product within just a few short weeks? It’s true.

Liquid injection molding (LIM), an industrial fabrication process, molds materials into a variety of components and products. It varies from the standard reaction injection molding

Injection molding is a complicated subject, one that may prompt many questions from you, our valued customers. If you are considering a liquid silicone project,

Liquid injection molding is a versatile process, with the ability to be customized to any application or need. And no matter what industry you’re in,

Rubber molding for keypad design has a wide spectrum of advantages because it’s just so versatile. This is critical in the medical industry. Your keypad

From comfort to control, modular options are the holy grail of customer-facing needs. As a business, you need to incorporate a product that gives you

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.