Silicone Molding – What are the differences?

Liquid silicone molding or LSR for short varies greatly from standard plastic injection molding. From the process as a whole, to the properties of the

Liquid silicone molding or LSR for short varies greatly from standard plastic injection molding. From the process as a whole, to the properties of the

Options: This is what today’s customers want. They don’t want a narrow offering from your company; they want the freedom to explore what best suits

Mold design is the most critical step in the production of silicone parts. But before you can start a mold design, it is important to

You may have heard that we are the #1 choice for silicone injection molding needs all across the country. Well, it’s true. But that’s not

Here at SiTech, we specialize in more than just molding silicone rubber keypads. We manufacture various silicone products, including: gaskets, seals, grips, isolators, electronic contacts

Silicone keypads vs. touch screens: everyone seems to have their own opinion on which is better. But we know silicone keypads have distinct advantages over

RoHS Directive 2015/863/EU RoHS / REACH / WEEE / BIOCIDAL / ASBESTOS / Prop 65. In accordance with the provisions of the Directive 2015/863/EU-RoHS, the

From boardroom to end product, your ideas need to come to fruition quickly. The faster you can get a product to market, the faster you

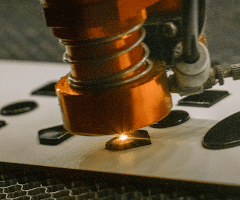

Laser marking is a fascinating process that has many complex stages. Yet the end result is quite simple and durable. In general, this permanent process

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.