Sanitizing Silicone Keypads & Components

Healthcare and pharmaceutical providers of all kinds, from hospitals and doctor’s offices to laboratories and urgent care facilities, need many machines, devices and tools to

Healthcare and pharmaceutical providers of all kinds, from hospitals and doctor’s offices to laboratories and urgent care facilities, need many machines, devices and tools to

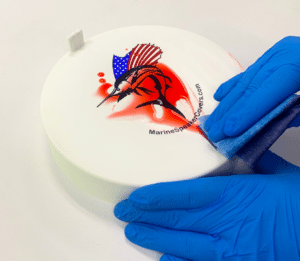

From graphic overlays and actuator options to backlighting and embossing, there are many ways to customize the look and feel of your silicone rubber keypads.

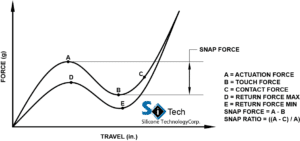

Silicone molded keypads made at Si-Tech are used in countless devices from aviation equipment to medical. The design of a tactile keypad is simple but elegant

All silicone rubber keypads share some common features. Not only do they have a unique and pleasing tactile feel, they are easy to clean and

The medical industry is one of the largest sectors of the global economy. Every day we rely on doctors, nurses, and other medical professionals. However,

Silicone has many versatile uses, and it’s not going anywhere any time soon. In fact, the global silicone market size is projected to reach 23

Silicone has many wonderful qualities, not the least of which is its thermal stability, which means this material is able to withstand extreme temperatures while

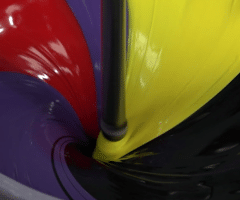

Here at Silicone Technology Corp. (Si-Tech Corp.) we utilize a worldwide standardized color system known as “Pantone Color Matching System” (PMS). To match colors of

Any time you have the public touching a common interface, whether that’s an ATM or soda fountain kiosk, durability has to be a main concern.

Silicone Technology Corp. manufactures out of Newport News, Virginia. Custom silicone rubber keypads are just one of the many products manufactured by Silicone Technology Corp. We use a unique injection molding process with Dow and Momentive Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products.