Overlooked Cost Factors

Communication, Quality and Design support are often factors that are overlooked when choosing a manufacturer. The main reason for domestic companies to buy offshore is low product cost. Often by focusing just on product cost, other costs get overlooked. The issues not taken into account when calculating this factor are the costs related to communicating back and forth, design of the product and using the correct material. How are quality issues handled? What about color approvals and first article for tool approval? These are savings that can be acquired during the design phase of the product and not during the manufacturing phase. Most of the cost savings are achieved during the design phase, not the manufacturing phase.

Distance and Travel Expenses

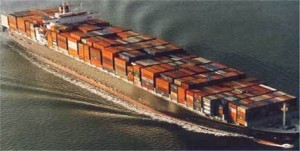

Shipping Charges

Another variable when buying offshore is shipping. There are two options by air or by sea. The overwhelming option is by sea, shipping by sea takes an average of three weeks, but it depends on weather, customs, etc. This can cause another issue, by using slow shipping, what happens if the job needs to have rework done or if the job needs to get expedited to meet demands? Fees are another factor to take into account. There are fees in getting the product from factory to port at both ends of the cycle. The company also needs to insure the shipment during delivery. If you choose to ship your product by air, that comes with its own host of fees.

Quality

Quality is a major aspect to consider. The manufacturing of silicone rubber products, such as silicone keypads, requires constant attention to achieve superior quality. Because of the low labor cost, many unskilled workers are used in the production process. This can result in a high percentage of defective low-quality parts. Materials are another factor in cost analysis. Gum stock or liquid silicone injection molding, quality and performance are the cost issues, depending on your and customers’ expectations of the final product.

ITAR Certified

Si-Tech is a competitive U.S. domestic silicone rubber keypad and component manufacturer. Contact us today at 757-887-8488 or at cs@sitech-corp.com to learn more.