One of the questions we get from some of our current and potential customers is if we have the capability to insert mold pre-made compression molded inserts into our custom silicone keypads and components. We strongly advise against cross contaminating different types of silicone rubber, especially if the rubber has been compression molded.

Here at SiTECH we use 100% liquid injection molding, or LIM for short. This method utilizes liquid silicone rubber instead of a high consistency rubber or gum stock. The high viscosity liquid silicone rubber used in LIM is made of two parts. An A and a B. Both parts are a liquid, but only one part contains the catalyst which is typically platinum. This method of molding provides a “closed-loop system” which basically means that the raw silicone is sealed from the moment it is placed on the machine, until the moment a silicone rubber product is made. This helps keep contaminations to a minimum. Lowering the amount of handling of the silicone rubber also decreases the chance of contamination of the silicone components.

Compression molding is one of the more commonly used methods of molding silicone rubber products, especially overseas. Compression molding is also one of the more simple methods of molding silicone rubber products, however it utilizes an open-air and labor intensive process.

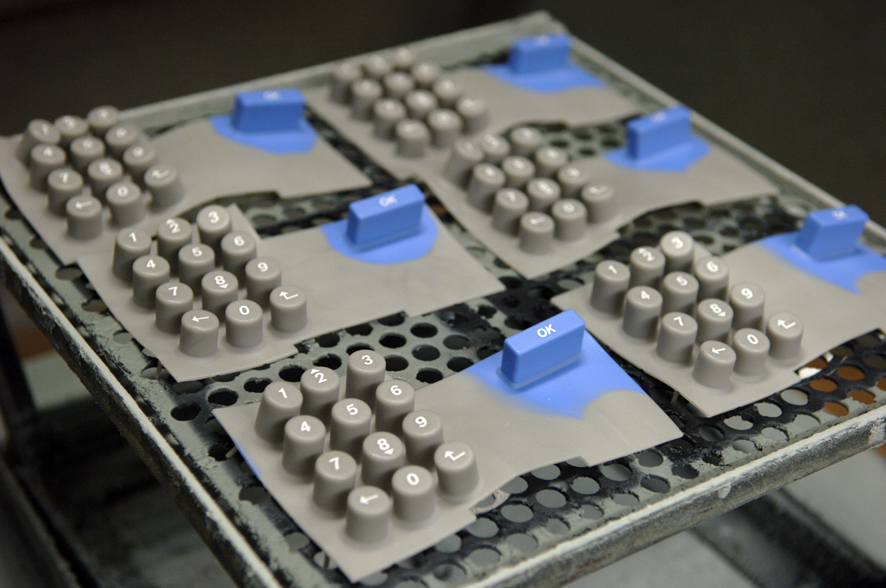

The silicone rubber used in compression molding is pre-catalyzed by adding powder to the silicone. This enables the silicone to cure once introduced to heat. To add pigment to the silicone, the silicone must be mixed using a two-mill roll. This is a labor intensive process that has the possibility for contamination of the silicone. Once the material is pre-catalyzed and pigment is added it is weighed and often reshaped to the approximate size and configuration of the desired part. The material is then directly placed into the mold cavity. The machine then closes and compresses the material between the two mold halves. Compression molding machines utilize heated molds to melt the silicone and vulcanize.

Due to the use of additives typically used in compression molding, a true cross link bond cannot be made between LIM silicone rubber and Compression molded rubber. This is the main reason we try to advise against cross contaminating the two types of molded rubber. Not having a cross link bond leaves the silicone rubber keypad or component open to tears, inserts falling out, and improper bonding.

We recommend having both inserts and overmold done using the same material by the same supplier. This will insure that the silicone properly bonds to each other. SiTECH is a domestic silicone rubber manufacturer located in Newport News, Virginia. We do everything from custom silicone molding to assembling parts in-house. At SiTECH we have more than 75 combined years of experience with liquid silicone injection molding and insert molding. Contact us at (757) 887-8488, or request more information or a quote on our home page, www.SiTech-corp.com.