While designing a new silicone rubber component or keypad it helps to use the fundamental rules of dimensioning and tolerancing. Using these rules allow you to focus your dimensions and tolerances to the key features of your design. These features may be the ones that perform a function or interact with other components within your final assembly. Below are a few summarized rules from the American Society of Mechanical Engineers standard: ASME Y14.5-2009. These rules are a general guideline for understanding the purpose of good dimensioning practices.

- Dimensioning and tolerancing shall clearly define engineering intent.

- Dimensions must not be subject to more than one interpretation.

- Dimensions should be shown in true profile views and refer to visible outlines on the part.

- Each necessary dimension of an end product should be shown.

- No more dimensions than those necessary for complete definition should be given.

- Dimensions should be arranged for optimal readability if at all possible.

- The complete drawing should define the part without specifying the manufacturing process.

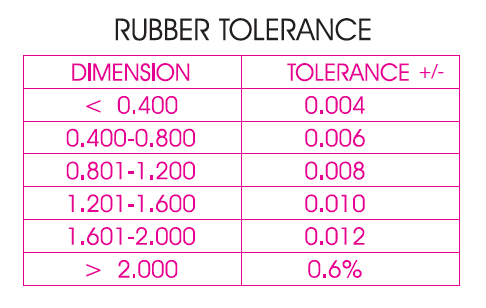

- Every dimension shown (other than reference, minimum, maximum, or stock) should have a tolerance.

- The use of reference dimensions should be minimized.

- Dimension tolerances should be located within the title block or shown as a note on the drawing.

- Dimensions and tolerances should only apply at the drawing level where they are specified.

These rules are a great start to understanding how a drawing of a component should be mapped out. The first few rules deal with how a drawing should look. These rules serve as guidelines to help engineers and designers to convey what they are trying to show in a concise and readable way.

Following these rules as much as possible is a great way to avoid unnecessary confusion when dealing with potential customers, or suppliers. Having a concise drawing that conveys everything needed allows for companies to quickly understand everything needed for your product, or what your product offers.

The last few rules not only add to helping cleaning up a drawing, but they also help manufacturers such as Si-Tech and suppliers down the line. Over controlling a component can significantly increase supplier cost and be detrimental to receiving your parts in a timely fashion. For example if quality must measure obscure dimensions that do not pertain the actual function of your assembly or component, then that just adds time and cost to your component.