NASA Space Shuttles

The moon landing was one of the most exciting events in American history, but did you know that silicone molding had a large part to play in making the mission a success? A safe landing on the moon would not have been possible without the use of silicone products in NASA space shuttles. From custom silicone keypads used in the shuttle command center to silicone adhesive used for thermal protection in fuselages, silicone technology has become a crucial part of past and future space missions.

Medical Devices

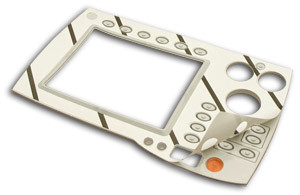

With just a single trip to the doctor for a check-up, any individual would be able to identify multiple products made from silicone injection molding. From heart monitors to blood pressure testing, to ultrasound systems; the work of many hospitals would be much more difficult without the use of silicone. Each of these products requires custom silicone molding for keypads, buttons, and other applications. Since its invention in the 1960’s silicone has played a crucial role in the medical field.

Automotive Races

Automotive races have become increasingly popular in America. As drivers race around the tracks of Nascar and Indycar at speeds approaching 200mph, they probably aren’t thinking much about silicone molding. Even though their focus is on the race, silicone technology is at work to get them to the finish line. Underneath the hood of thousands of high-performing vehicles are custom silicone seals used for head gaskets, control arm joints, valve covers and more. The durability of silicone seals has made them the ideal choice for many automotive applications.

It’s truly amazing to see the wide variety of applications that silicone technology has had throughout history. Custom silicone molding is an integral part of many business operations in nearly every industry. To find out if silicone molding can help your business make a leap into the history books, contact SiTECH today.