Deciphering the Force Curve in Tactile Silicone Rubber Keypads

When it comes to the design and functionality of tactile silicone rubber keypads, one of the most technical yet crucial aspects to consider is the force curve. This graphical representation doesn’t just define the user experience by detailing the tactile feedback but also informs the engineering process behind creating a keypad that’s both responsive and comfortable to use.

The Anatomy of a Force Curve

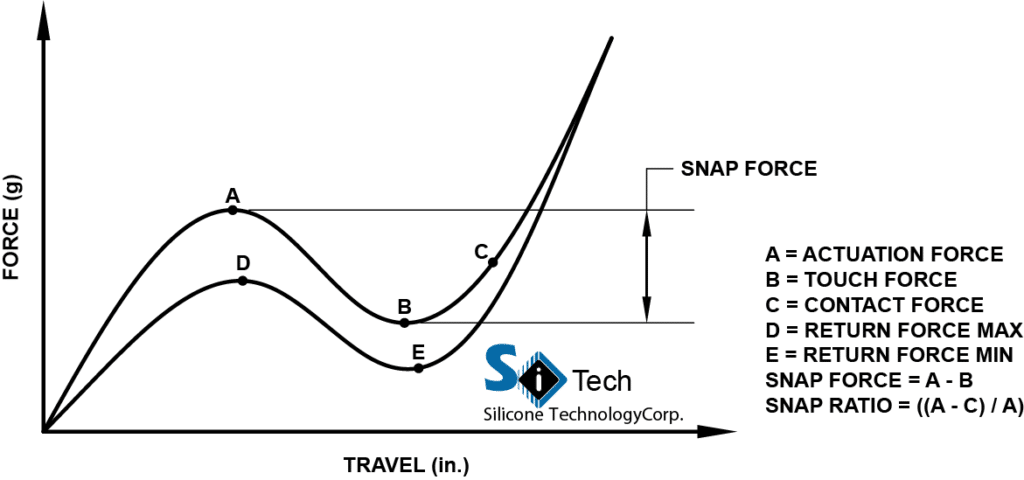

A force curve is essentially a map that details the journey of a fingertip from the moment it touches a key to when the key returns to its initial position after being released. Let’s dive into a typical force curve graph to understand the nuances of what makes a keypad’s tactile response just right.

Here are the critical points on the force curve you need to know about:

- Actuation Force (A): This is the crucial moment of contact — the exact point where enough pressure has been applied for the key to register a press. This force must be precise; too high, and the key feels stiff, too low, and it may lead to accidental actuation.

- Touch Force (B): It’s the initial resistance you feel when you begin to press a key. This resistance is important for preventing unintentional presses.

- Contact Force (C): This lower force is what’s needed to maintain contact with the switch once the key has been actuated. It’s essential for ensuring that the key doesn’t send multiple signals if the pressure varies slightly during a press.

- Snap Force: Represented by the distance between points A and B, snap force gives the user that satisfying click or snap, indicating that the key has been successfully pressed. It’s a critical element for feedback in gaming keypads or devices where confirmation of a keypress is vital.

- Return Force Max (D) and Return Force Min (E): After the key is released, it doesn’t just spring back instantaneously; there’s a range of force with which it returns to the original position. This return force must be optimized to prevent fatigue during rapid typing or repeated presses.

- Snap Ratio: Defined by the equation (A−C)/A, the snap ratio quantifies the tactile ‘click’ feeling. A higher ratio typically means a more pronounced tactile feedback.

Factors Affecting the Force Curve

Several factors influence the shape of the force curve in silicone rubber keypads:

- Material Hardness: Measured in Shore A, the hardness of the silicone material affects how much force is needed to deform the key.

- Key Design: Dimensions like height, wall thickness, and the shape of the key (dome-shaped, flat, etc.) play a significant role.

- Underlying Structure: The design of the contact point (e.g., carbon pills, gold contacts) also influences the force curve.

Calculating the Force Curve

- Step 1: Material and Design Analysis

- Analyze the silicone material’s properties, including its hardness and elasticity.

- Consider the design parameters of the keypad, such as key size and shape.

- Step 2: Prototype and Measurement

- Create a prototype keypad based on the design parameters.

- Use a force gauge to measure the force at various points of key displacement.

- Step 3: Graphing the Data

- Plot the measured force against the corresponding displacement to create the force curve.

- Identify the pre-contact and post-contact regions and any points of interest (like the actuation point).

- Step 4: Analysis and Iteration

- Analyze the curve for desired qualities (e.g., a smooth increase in force, a clear tactile feedback point).

- Make adjustments to the keypad design and repeat the measurement process if necessary.

- Practical Applications

The force curve is a vital component in the design of tactile silicone rubber keypads. By carefully analyzing and adjusting the materials, design, and underlying structure, manufacturers can create keypads that offer an optimal balance of comfort, functionality, and durability. Understanding the force curve not only enhances the user experience but also contributes to the overall success and usability of the electronic device.

If you are looking for more information regarding force curve, or would like to have your silicone rubber product reviewed, please reach out to us at 757-887-8488 or submit a quote here