There is lot of buzz about Liquid Silicone Injection. Due to the overwhelming increase in popularity, many misconceptions have also formed about this remarkable material. SiTECH has been working with Liquid Silicone Injection for years, and we have seen just how useful it can be for a wide variety of applications. Today, we are using our experience to dispel some of the common misconceptions about Liquid Silicone Inject.

Liquid Injection is Expensive

Since popular materials often come with a high price tag, some product designers and engineers think that liquid injection molding is going to break the bank. However, this material is not only cost effective, it may also save you money during the manufacturing process. Liquid Injection combines with Rapid Prototyping will allow your team to review all of the details before committing to a final product. This gives you the freedom to identify changes before creating the final product. A solution that will save your company in the long-run.

Injection Molding has Design Limitations

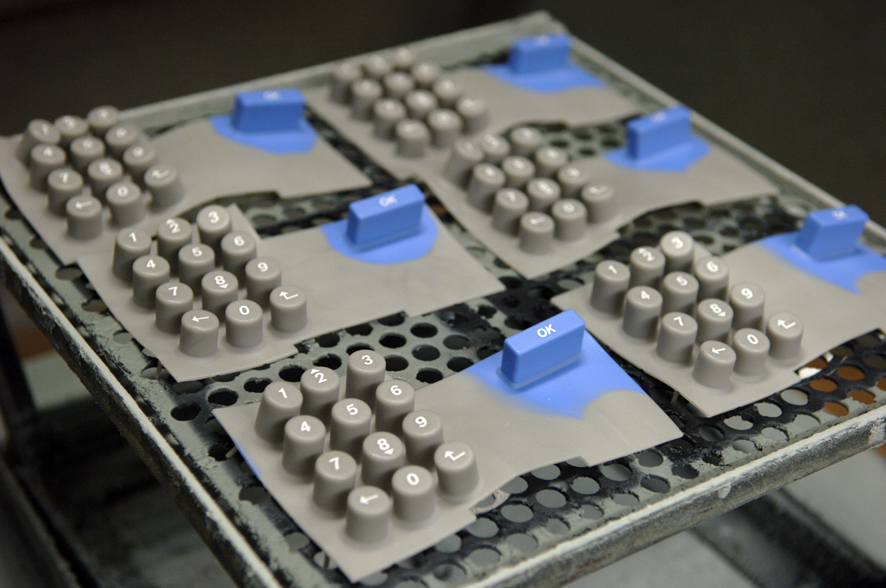

This is one of the biggest misconceptions about injection molding. In reality, liquid silicone is only limited by the imagination of the engineer or product designer. It is one of the most versatile materials in the manufacturing world today. Whether you need back-lit keys, chemical resistant materials, custom colors, or other features, liquid injection is able to meet all of these custom needs and more. Other forms of silicone, such as gum stock, have limited options when it comes to customization.

Gumstock is a Better Alternative to Liquid Silicone

Gumstock, also called High Consistency Rubber is a type of silicone that has the consistency of a thick putty or dough. It is often used in compression molding by placing the silicone into an open-air molding press to form products. Before the rise of liquid injection molding, this was a popular form of silicone manufacturing. However, it is limited in terms of design and customization. The process is far more labor intensive and is restrictive to product designers.

Silicone Technology Corp. is headquartered in Newport News, Virginia. We use a unique liquid injection molding process with Dow and GE Silicones. This combination of technology and quality offers you a competitive domestic supplier of custom keypads and other silicone rubber products. If you want to find out more about what makes SiTECH different from our competitors, give us a call today at 757-887-8488.