Injection molding of silicone offers many advantages. In today’s SiTECH blog, we will talk about cover inserts. Insert molding is taking a pre-molded silicone part or component of a different material and inserting it in a mold, then injecting silicone around it and ending up with one part.

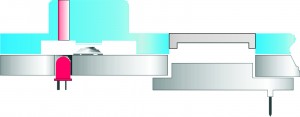

In the production of silicone rubber keypads, inserts can be used to enhance the performance and functionality of the part being produced. Inserts are molded in advance using silicone rubber injection molding. Many different silicone materials can be used to create varying degrees of durometer, or hardness. The most important part about injection molded silicone inserts is that they are permanent, not bonded or glued. A chemical cross-link occurs, which makes the insert the part. This ensures there will be no separation or leakage of inserts when cleaning or submerging them in water. This adds confidence when designing in display widows and light indicators.

Inserts offer many options when designing a keypad or front cover with a keypad. The insert can be clear, just as a piece of glass or plastic. This gives the designer the option of using displays and light indicators for feedback to the operator without any worry of moisture or contaminants getting into the equipment. It’s possible to add color to the inserts which are opaque or translucent to the insert. A big advantage with injection molding is that the insert can be pre-screened, giving the designer many options with recess areas or different shapes. Another advantage with injection molded silicone inserts is that the part has a crisp line separation from the insert to the part. There is no color bleeding, as with compression molding.

There are areas to pay close attention to when making the inserts. Thickness is very critical when the tool closes on the insert. You do want pressure, but not too much or it will deform the insert and cause problems with the final part. Three issues that can happen with injection molded silicone insert production are that the part’s edges will not be uniform, the insert will demonstrate out of shape or a different shape, and it can distort the part and render it non-functional. These problems happen with lack of experience or not using injection molded silicone parts. You must use the same curing agent for both the insert and the final part, or you will not get a chemical cross-link.